You've got the truck. You've got the vision. Now, you want that aggressive stance and the ground clearance to tackle bigger obstacles. You are wondering how to install a lift kit on a truck yourself to save some cash and earn some bragging rights. It might seem like a huge job reserved for professional mechanics, but with the right tools, a good bit of patience, and a solid plan, it's a project you can complete in your own garage. This installation guide will walk you through how to install a lift kit on a truck, step-by-step.

Icon Vehicle Dynamics lift kits are premium, performance-focused suspension systems designed to not only lift trucks and SUVs but also drastically improve both on-road comfort and off-road capability.

Before You Turn a Wrench

Jumping straight into the lift kit install is a recipe for a very long weekend. A little prep work goes a long way. Getting everything in order first makes the actual job much smoother.

Choosing Your Lift Kit

Not all lift kits are the same. You need to pick the one that's right for your truck and your goals. Your main choices are body lift kits, suspension lift kits, and leveling kits.

A body lift is a relatively simple option. These kits use spacers to raise the truck's body away from the frame. This modification gives you room for bigger tires without changing the factory suspension geometry.

-

Suspension lifts are more involved. This type replaces suspension components like the coil spring, shocks, and control arms to raise the truck's frame. This approach provides more ground clearance and greatly improves off-road performance for vehicles like a Ford Bronco or Jeep Wrangler.

-

Leveling kits are designed to correct your truck's factory "rake." Most trucks, like the Ford F-150 or Toyota Tacoma, come with a rake, meaning the back is higher than the front. A leveling kit raises just the front, making the truck sit level and allowing for slightly larger tires without a full lift install.

Make sure any kit you buy is specifically for your truck's make, model, and year, whether it's a GMC Canyon or Toyota Tundra. A full suspension lift kit installation is very different from installing a simple leveling kit. Some kits require cutting or drilling, so read the kit instructions before you buy. Davidson's Auto Gear has experts who can help you choose the perfect kit that balances your needs with your budget.

Gathering Your Tools

Having all your tools ready before you start the kit install is critical. Nothing is worse than getting halfway through and realizing you're missing something essential. You'll need a solid collection of basic hand tools and potentially some specialty power tools.

Here's a list of essential tools you'll likely need:

-

A good quality floor jack.

-

Heavy-duty jack stands (at least two, four is better).

-

A full socket set (both metric and standard sizes).

-

A set of combination wrenches.

-

A breaker bar for stubborn bolts.

-

A drive torque wrench for proper tightening.

-

Pry bars of various sizes.

-

Penetrating oil for rusty nuts and bolts.

-

Safety glasses and work gloves.

-

Potentially a coil spring compressor (use with extreme caution).

-

Wheel chocks to keep the truck from rolling.

-

A good set of drill bits if your kit requires drilling.

This list covers the basics for a lift kit installation. Always check the instructions with your suspension lift kit, as it might list other specific tools required for the job. You can often rent or buy tools from your local auto parts store if you don't own them.

During disassembly, you might discover worn parts like ball joints or tie rods. It is a good idea to have a plan for acquiring replacement parts quickly if needed. Davidson's Auto Gear keeps a wide inventory of replacement suspension parts, which can prevent frustrating delays in your project.

Safety Is Not a Suggestion

We need to talk about safety because this is serious stuff. You'll be working under a vehicle that weighs thousands of pounds. There is no room for cutting corners here if you want to prevent injury. Always work on a flat, level surface like a concrete garage floor. Never work on soft ground like dirt or asphalt on a hot day. Chock the wheels that will stay on the ground to prevent any rolling.

The floor jack is only for lifting the truck. Once it's up, you must support it with jack stands rated for your vehicle's weight. Never, ever get under a vehicle that's only held up by a jack. Lastly, disconnect the negative battery terminal from the negative battery post. This simple step prevents any accidental electrical shorts while you work. Safety should be your top priority throughout the entire kit installation process.

The Guide on How to Install a Lift Kit on a Truck

With your prep work done, it's time for the fun part. The exact installation steps will vary a lot based on your truck and your specific kit. Always treat the manufacturer's installation instructions as your main guide; this is a general overview.

Getting the Truck Ready

First, park the truck on your level surface and engage the parking brake. Loosen the lug nuts on the wheels you'll be removing first, but don't take them off yet. It's much easier to break them loose while the truck is on the ground.

Place your wheel chocks behind the rear tires if you're starting on the front suspension. Use your floor jack to lift the front of the truck at the recommended jack points. Once it's high enough, place your jack stands securely under the frame rails and slowly lower the truck onto them. Now you can completely remove the wheels and set them aside. This is also a good time to spray any rusty nuts and bolts with penetrating oil to make them easier to remove. Let the oil soak in while you prepare your tools.

Working on the Front Suspension

The front suspension is usually more complicated than the rear. You'll have steering components and often a more complex strut or coilover setup. Take your time, stay organized, and keep track of all the hardware you remove.

You will likely start by disconnecting the sway bar end links from the lower control arm. You may also need to disconnect the tie rod ends from the steering knuckles. Use a special tool for this if you have one, or a few firm taps with a hammer on the knuckle can work.

Next, you'll tackle the main suspension components. This usually means removing the entire strut assembly. You'll need to unbolt it from the lower control arm at the bottom and from the strut tower in the engine bay at the top.

If your kit uses strut spacers, this is where you install them. For kits with new springs, you may have to use a spring compressor to take the strut apart. This is a dangerous step, as spring compressors hold a huge amount of energy, so be extremely careful and follow all safety instructions.

Once your new parts are in or the spacers are added, you can reinstall the strut assembly. Use the new hardware that came with your kit. Reconnect the sway bar links and tie rod ends, and use your drive torque wrench to tighten everything to the specs listed in your installation guide.

Moving to the Rear Suspension

The rear suspension is often simpler, especially on trucks with a rear leaf spring setup. Start by using your floor jack to lift the rear of the truck. Support the frame with jack stands just in front of the rear axle.

You can leave your floor jack under the rear differential to help you raise and lower the axle as needed. For trucks with leaf springs, the process usually involves installing lift blocks to raise the rear height. You'll need to remove the stock U-bolts that hold the axle to the leaf springs.

With those off, you can lower the axle enough to slide the lift block between the axle and the leaf spring. Your kit will come with new, longer U-bolts. You absolutely must use them; the old ones are too short and have been stretched.

Place them over the leaf spring and through the axle plate, and tighten them down evenly. Pay close attention to the correct torque specifications, as this is very important for safety. Using the right drive torque is critical here.

If your truck has rear coil springs, the process is more like the front. You'll support the axle, disconnect the shocks and any track bars, then lower the axle to remove the stock springs and install the new ones. Many lift kits also come with longer rear shock absorbers, which you will install last. With everything in place, put the wheels back on but don't fully tighten the lug nuts just yet.

After the Installation

You've installed all the parts and the truck is sitting tall, but you are not quite done yet. A few final steps are needed to make your lifted truck safe and ensure it drives correctly. Completing these post-installation tasks is just as important as the lift install itself. Skipping them can lead to problems down the road. Take the time to do it right.

Final Checks and Torque

With the truck back on the ground, it's time to torque everything. Tighten the lug nuts in a star pattern to the proper spec. Go back over every single nut and bolt you touched during the installation and check the torque with your torque wrench. It is also smart to re-check all the nuts and bolts after driving about 50 to 100 miles. Things can settle and might need a final tightening. This is a step many people forget, but it is important for long-term safety and can prevent uneven tire wear.

Get a Professional Wheel Alignment

This step is not optional. Changing the suspension height completely alters your truck's alignment geometry. Driving without a proper alignment will cause poor handling, a crooked steering wheel, and will destroy your tires in a short time, leading to uneven tire wear. Take your truck to a good alignment shop as soon as possible after the lift. Tell them you just installed a suspension lift so they know to check all alignment angles. A proper alignment is critical to vehicle safety and tire life after a lift.

Adjust Your Headlights

Lifting your truck also raises your headlights. They'll now be aimed much higher, which can blind oncoming drivers at night. This is both annoying and dangerous for you and other drivers on the road.

You need to adjust your headlights back down. Most trucks have adjustment screws near the headlight assembly. Park your truck on level ground facing a wall or garage door and follow a simple guide to aim them correctly. It's a small detail that makes a big difference for nighttime visibility and safety.

After your lift kit is installed, you might get inspired to do more. Many owners of Ford Broncos or Toyota Tacomas add other accessories like a tonneau cover to protect their gear or rugged Husky Liners and seat covers to protect the interior. Davidson's Auto Gear can help you with these accessories and installation, as these projects are much simpler than a suspension lift and can further customize your truck.

Conclusion

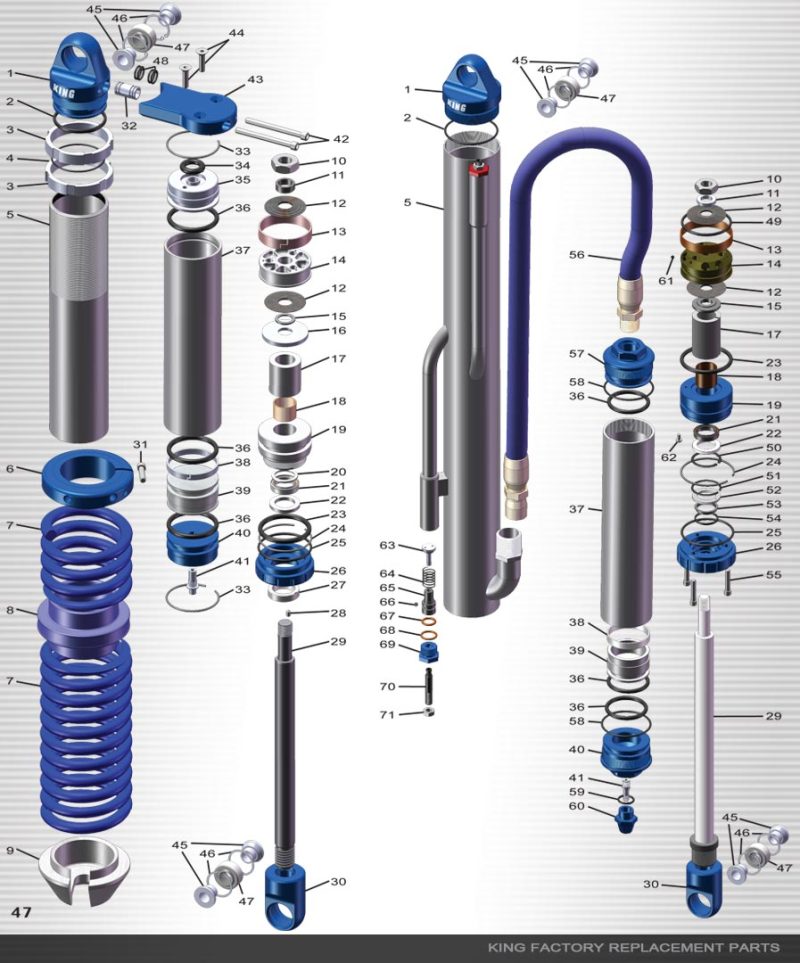

King Lift Kits, featuring their iconic blue shock bodies, are race-proven, adjustable coilover and bypass shock systems favored by off-road enthusiasts for their superior damping ability and tunable performance across any terrain.

Finishing the job of how to install a lift kit on a truck is a great feeling. You have transformed the look and capability of your vehicle with your own two hands. Contact us today if you need more assistance.